Manual A Type Layer Poultry Cages for 5000-10000 birds

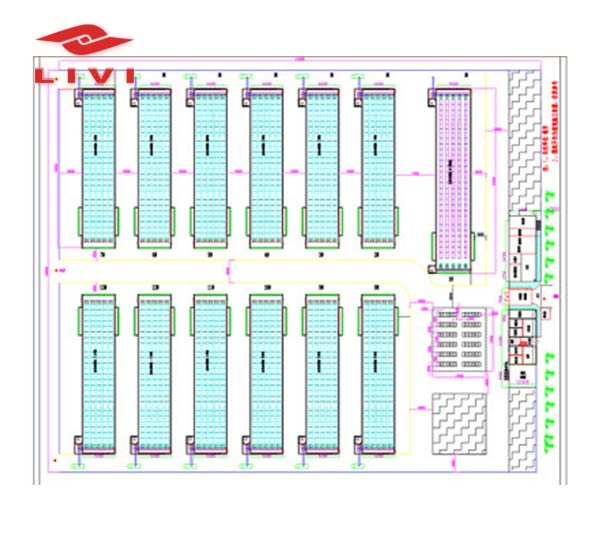

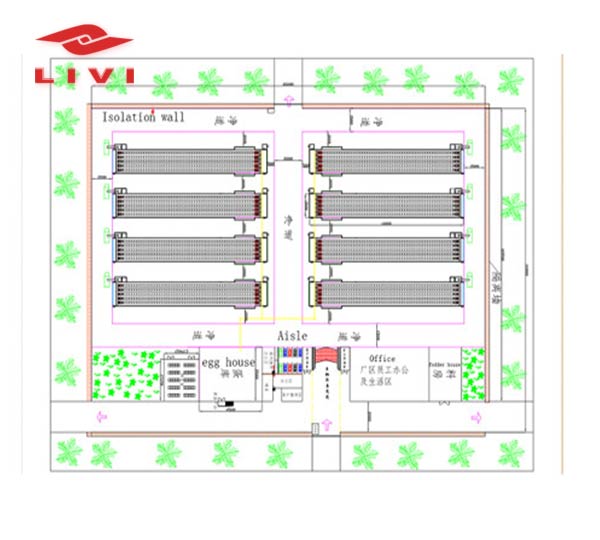

Manual A-type layer cage system usually used for 5,000-10,000 birds chicken farms. We can provide free chicken house design according to our customers’ requirements. You just need to tell us how many chicken you are going to raise, then we can supply all details you need.

Product description

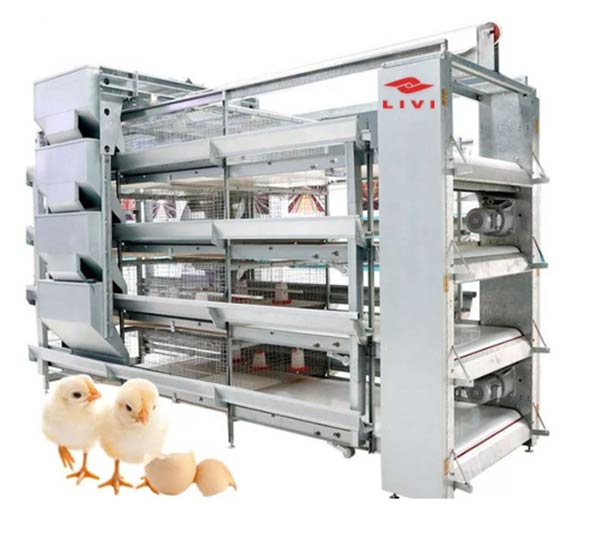

Introduction of Manual A Type Layer Poultry Cages

The manual A-type laying hen poultry cage is a common poultry raising equipment used to raise laying hens. It is mainly made of high-quality galvanized steel wire mesh, which is strong and durable.

The advantages of the manual A-type laying hen poultry cage are its simple structure and easy operation, which is suitable for use in small-scale poultry farms.

The manual A-type laying hen poultry cage is an important piece of equipment for modern poultry breeding and is of great significance to the development of the poultry breeding industry.

Features of Manual A Type Layer Poultry Cages

1. High-quality materials: The manual A-type layer poultry cage is made of high-quality galvanized steel wire mesh, which is corrosion-resistant and durable, can be used for 15-20 years.

2. Simple structure: Its A-shaped design maximizes the utilization of the chicken house space and effectively improves the utilization rate of the chicken house.

3. Easy to clean: Manual A-type layer poultry cages are easy to clean and can reduce the spread of diseases.

4. Improve egg production rate: Manual A-type layer poultry cages provide a safe, comfortable and efficient raising environment for laying hens, the egg production rate can usually reach 95%.

5. Wide scope of application: The manual A-type laying hen poultry cage is suitable for use in small-scale poultry farms, providing farmers with an economical and practical choice.

Why choose us ?

Our service are from design schemes of turnkey poultry farm project, product introduction, offer quotation, delivery, installation instruction, equipment maintenance, to farm instruction and so on

30 years poultry equipment R&D and manufacturing

Our team is ready to service you 24 hours online

Specification of Manual A Type Layer Poultry Cages

| Model | Capacity | Cages Size(L*W*H) | Cell Quantity | Cell Size(L*W*H) | Surface | Material |

| A-96 | 96 Birds | 1.9M*2.3M*1.65M | 4 | 0.47M*0.36M*0.36M | Galvanized | Q235 |

| A-120 | 120 Birds | 2.2M*2.3M*1.65M | 5 | 0.44M*0.36M*0.36M | Galvanized | Q235 |

| A-128 | 128 Birds | 1.9M*2.5M*1.95M | 4 | 0.47M*0.36M*0.36M | Galvanized | Q235 |

| A-160 | 160 Birds | 2.0M*2.5M*1.95M | 5 | 0.39M*0.36M*0.36M | Galvanized | Q235 |

| A-200 | 200 Birds | 2.0M*2.8M*2.2M | 5 | 0.39M*0.36M*0.36M | Galvanized | Q235 |

Accept customers’special sizes

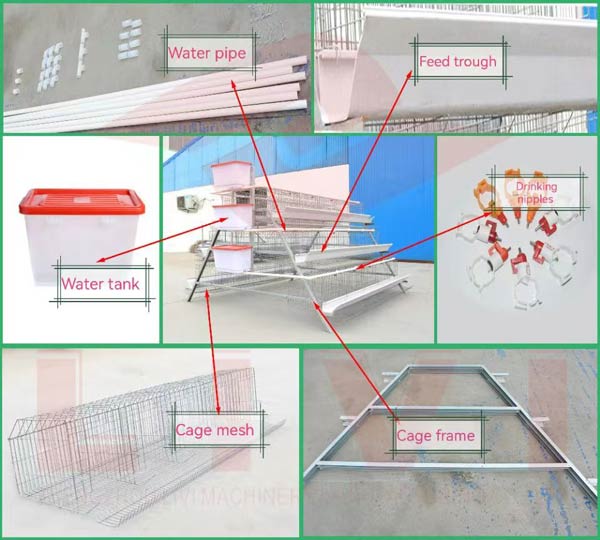

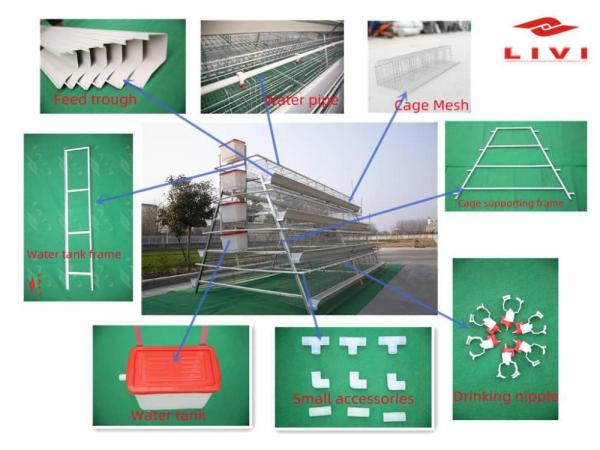

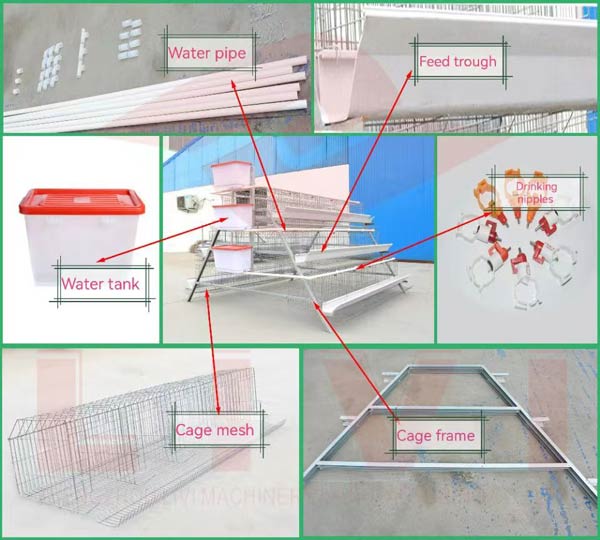

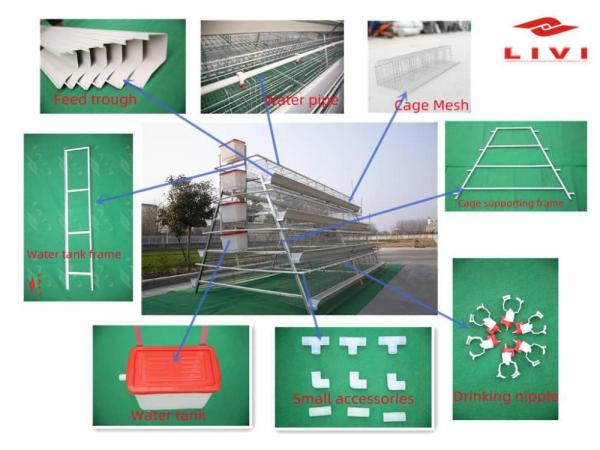

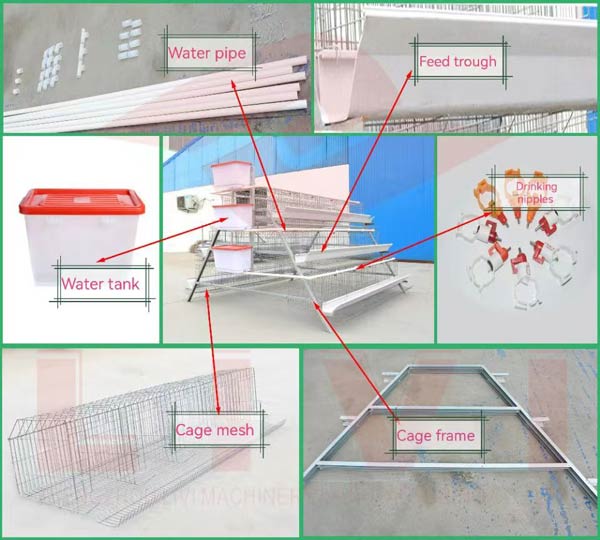

Fitting

Battery poultry cage mesh and frame, nipple drinker, water pipe and connector, water tank, water pressure regulator, water filter, medicine doser, feeding trough with connector, battery cage mesh clips and pliers, battery cage frame nuts and screws

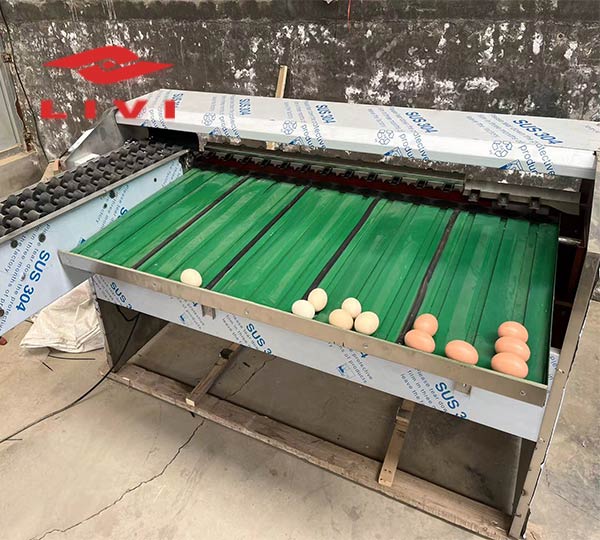

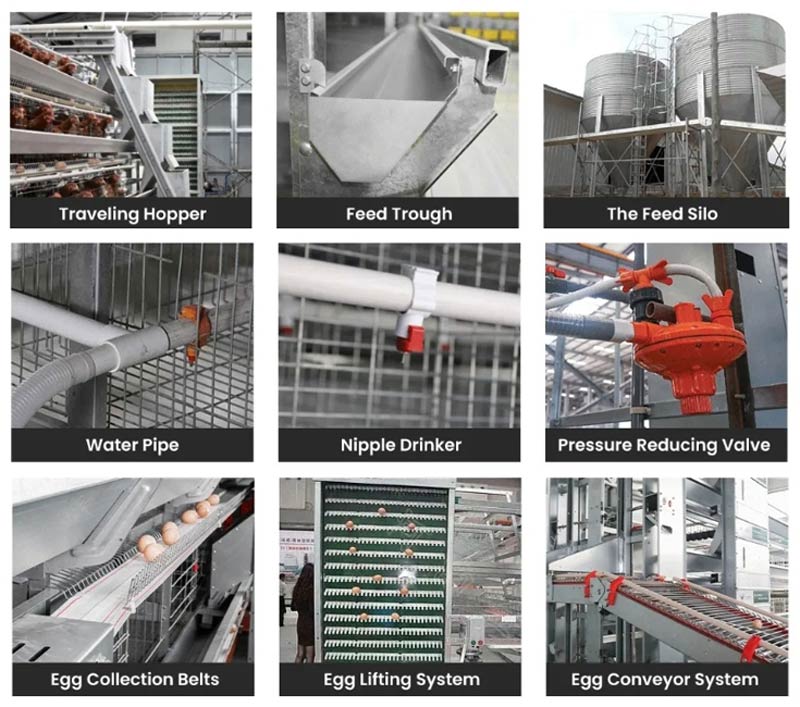

Automatic corollary system

The parts are automatic electric control cabinet, automatic feeding system, automatic drinking system, manure removal system

Automatic electric control cabinet

The each button independently controls different devices and 2- 3 workers can manage the entire automatic system in the chicken house with 30,000 birds or more