When it comes to poultry farming, choosing the right type of chicken cage is crucial for the health and productivity of the chickens. The two main types of cages used in poultry farming are A-Type and H-Type. Each has its own set of advantages and disadvantages, and the choice between them often depends on the specific needs of the farm, including space, budget, and management practices. Here’s a comparison of A-Type chicken cages and H-Type chicken cages:

A-Type Chicken Cage

Design:

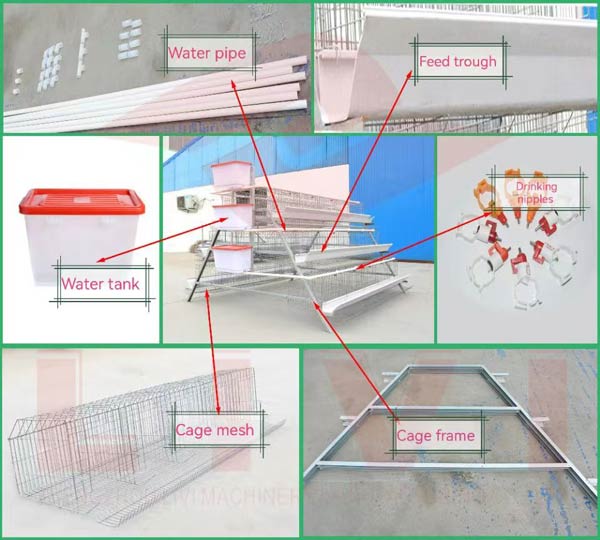

- A-Type chicken cages have a simple, triangular structure (resembling the letter “A”) that allows them to be easily stacked in tiers. They are typically made of wire mesh.

Advantages:

- Cost-Effective: Generally, A-Type chicken cages are less expensive to purchase and install than H-Type cages.

- Good Ventilation: The open design allows for good air circulation, which is beneficial for the health of the chickens.

- Ease of Management: Collecting eggs and cleaning are relatively easy due to the accessible design.

Disadvantages:

- Space Utilization: They may not utilize vertical space as efficiently as H-Type cages, potentially requiring more land area for the same number of chickens.

- Lower Density: Because of their structure, A-Type chicken cages might not support as high a density of chickens per unit area as H-Type chicken cages.

H-Type Chicken Cage

Design:

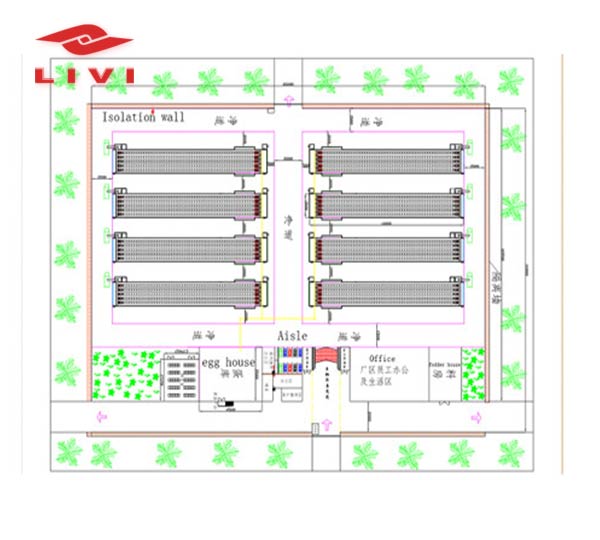

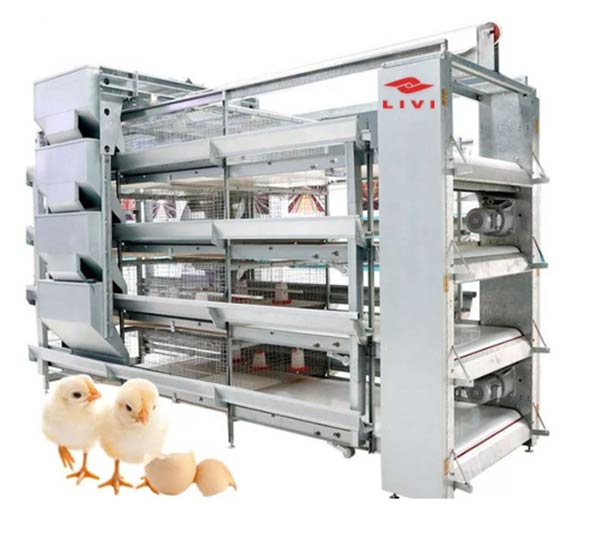

- H-Type chicken cages are more complex, with a double-sided structure that maximizes space utilization. They are named for their resemblance to the letter “H” when viewed from the end.

Advantages:

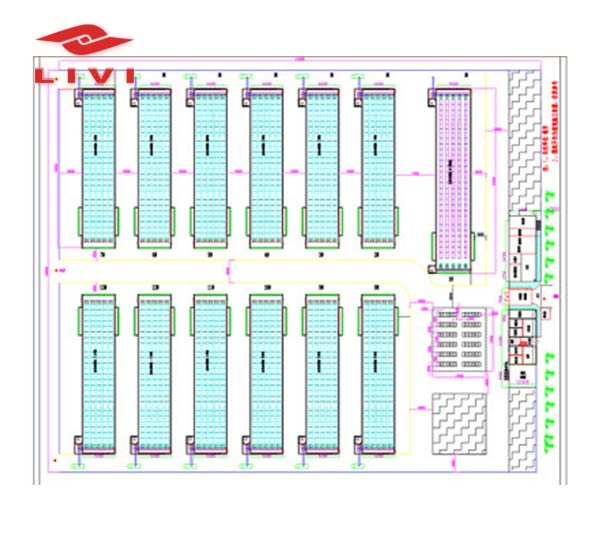

- High Density: These cages can accommodate more chickens in a smaller footprint due to their efficient use of vertical space.

- Scalability: H-Type chicken cages are well-suited for larger, more industrial operations because they can be easily scaled up.

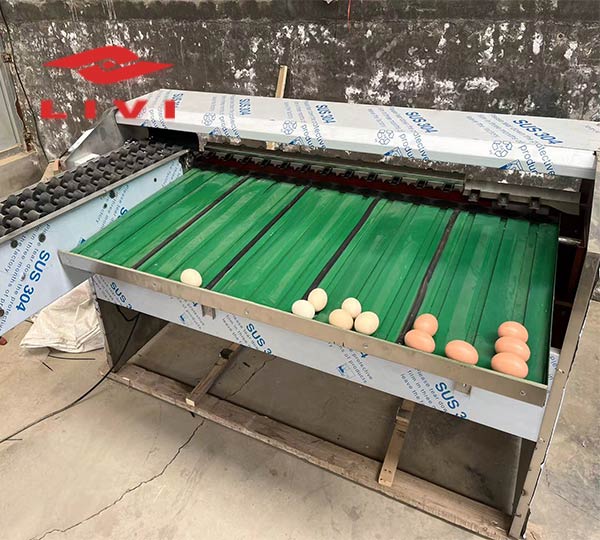

- Automated Systems: They are often designed to integrate with automated feeding, egg collection, and waste removal systems, reducing labor costs.

Disadvantages:

- Cost: H-Type chicken cages are generally more expensive to purchase and install due to their complexity and the higher likelihood of needing automated systems.

- Maintenance: The complexity and automation of H-Type chicken cage systems can make maintenance more challenging and potentially more costly.

- Ventilation: Ensuring proper ventilation can be more difficult with H-Type chicken cages, especially in densely populated setups, which may require additional investment in environmental control systems.

How to Choice A-Type Chicken Cage and H-Type Chicken Cage

The choice between A-Type chicken cages and H-Type chicken cages depends on various factors, including the scale of the poultry operation, budget constraints, and management preferences. A-Type chicken cages might be more suitable for smaller farms or those with limited budgets, while H-Type chicken cages could be the better choice for larger, more industrialized operations looking for efficiency and scalability. Proper management and care are essential, regardless of the cage type, to ensure the health and productivity of the chickens.

LIVI A-Type Chicken Cage and H-Type Chicken Cage

We are LIVI poultry equipment supplier, providing various types of high-quality chicken cages, including Type A and Type H, which can be used for laying hens, broilers and chicks. We have our own factory and can provide you with chicken cages at factory direct prices, feel free to contact us for a free quote. Our email: [email protected]