The poultry industry in Zimbabwe has seen remarkable growth over the years, with broiler farming playing a significant role in meeting the demand for chicken meat. Establishing a large-scale broiler cage breeding project for 20,000 birds can be a highly profitable venture, provided that the right strategies, equipment, and management practices are employed. This comprehensive guide will explore the essential aspects of setting up and managing a broiler cage breeding project in Zimbabwe, focusing on broiler breeds in Zimbabwe, broiler cages in Zimbabwe, and poultry equipment in Zimbabwe.

Planning the Broiler Cage Breeding Project

Selecting the Right Broiler Breeds in Zimbabwe

Choosing the right broiler breeds is crucial for ensuring high growth rates, feed efficiency, and overall productivity. Broiler breeds in Zimbabwe are selected based on their adaptability to local conditions, growth performance, and market demand.

- Popular Breeds: Some of the popular broiler breeds in Zimbabwe include Cobb 500, Ross 308, and Arbor Acres. These breeds are known for their rapid growth, excellent feed conversion ratios, and suitability for intensive farming.

- Considerations: When selecting broiler breeds, consider factors such as the availability of chicks, disease resistance, and the specific requirements of your farming system.

Designing the Broiler Cage System

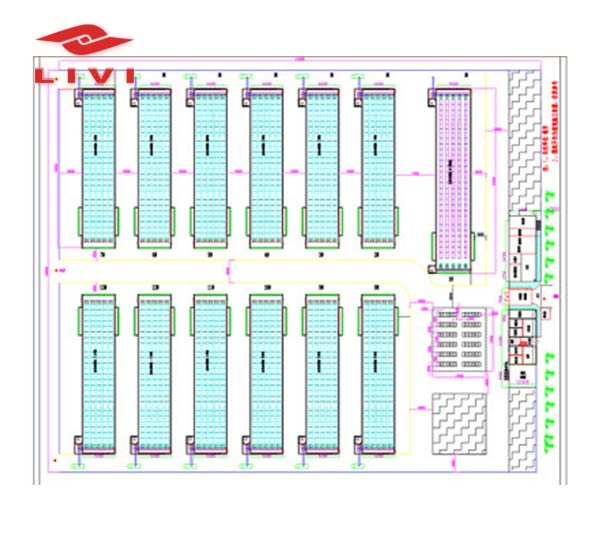

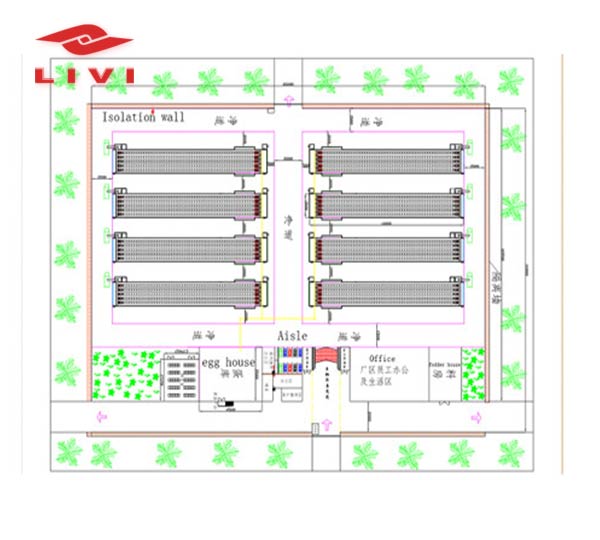

The design and layout of the broiler cage system play a pivotal role in the success of the project. Proper planning ensures optimal space utilization, efficient management, and high productivity.

- Broiler Cages in Zimbabwe: Broiler cages are designed to house broilers in a controlled and efficient environment. These cages are available in various configurations and sizes to suit different farming scales.

- Capacity and Layout: For a 20,000 broiler cage breeding project, you will need to calculate the number of cages required based on the capacity of each cage. Ensure that the layout allows for easy access for feeding, watering, and cleaning.

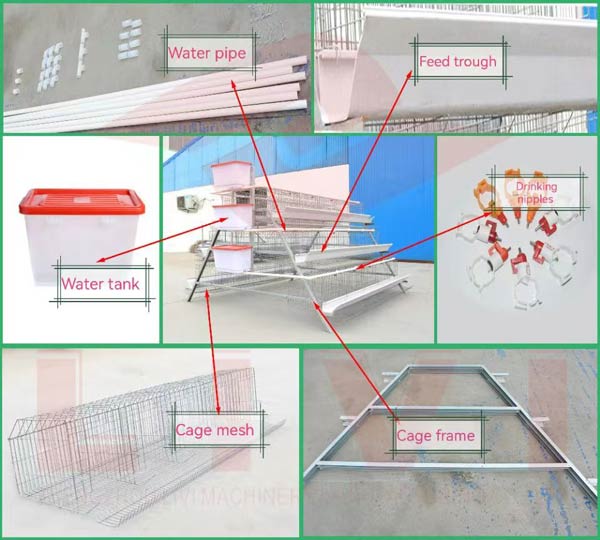

Essential Poultry Equipment in Zimbabwe

Broiler Cages

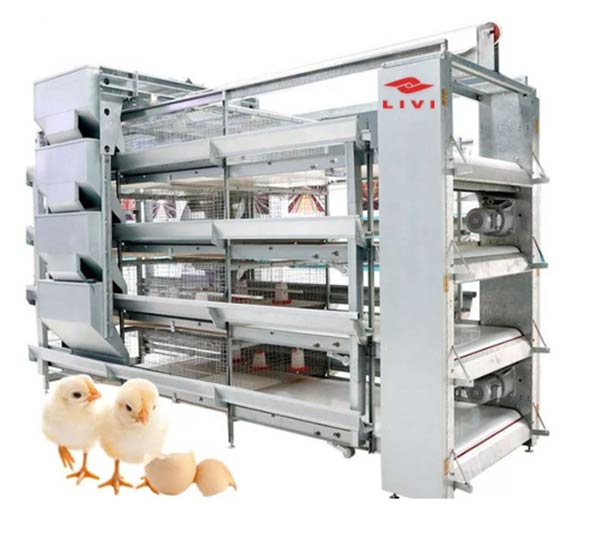

Investing in high-quality broiler cages is essential for the success of the project. LIVI Poultry Equipment Factory offers a range of durable and affordable broiler cages in Zimbabwe.

- H-type Broiler Cages: These cages are designed for high-density housing, maximizing space utilization while ensuring the welfare of the birds. They come equipped with features such as automated feeding and watering systems.

- A-type Broiler Cages: Suitable for smaller operations, these cages provide a comfortable environment for broilers and are easy to manage.

Feeding and Watering Systems

Automated feeding and watering systems are crucial for ensuring that broilers have constant access to food and water, promoting healthy growth and reducing labor costs.

- Feeders: Automated feeders ensure a consistent supply of feed, reducing wastage and ensuring that all birds have access to food.

- Waterers: Nipple drinkers and bell drinkers are popular choices for broiler cages, providing a constant supply of clean water.

Climate Control Systems

Maintaining an optimal environment is essential for the health and productivity of broilers. Climate control systems help regulate temperature, humidity, and ventilation within the broiler house.

- Ventilation: Proper ventilation is crucial for maintaining air quality and preventing respiratory issues. Exhaust fans and air inlets can be used to ensure adequate airflow.

- Heating and Cooling: Depending on the climate, you may need heating systems such as brooders and cooling systems such as evaporative coolers to maintain a comfortable temperature for the broilers.

Waste Management Systems

Efficient waste management is essential for maintaining hygiene and preventing disease outbreaks. Manure removal systems can help manage waste effectively.

- Manure Belts: These systems collect and remove manure from the cages, maintaining a clean environment and reducing the risk of disease.

- Composting: Composting the manure can provide an additional source of income and reduce environmental impact.

Management Practices for the Broiler Cage Breeding Project

Feeding and Nutrition

Providing a balanced diet is crucial for the growth and productivity of broilers. The feed should be formulated to meet the nutritional requirements of the broilers at different stages of growth.

- Starter Feed: High in protein and energy, starter feed is given to broilers during the first few weeks of life to promote rapid growth.

- Grower Feed: Given during the intermediate stage, grower feed supports continued growth and development.

- Finisher Feed: Given during the final stage, finisher feed helps achieve the desired market weight and improves meat quality.

Health and Biosecurity

Maintaining the health of the broilers is vital for the success of the project. Implementing stringent biosecurity measures helps prevent disease outbreaks and ensures the welfare of the birds.

- Vaccination: Regular vaccination programs should be implemented to protect broilers from common diseases such as Newcastle disease, infectious bursal disease, and avian influenza.

- Biosecurity Measures: Implement measures such as footbaths, restricted access to the broiler house, and regular cleaning and disinfection to prevent the introduction and spread of diseases.

Monitoring and Record-Keeping

Regular monitoring and record-keeping are essential for managing the broiler cage breeding project and making informed decisions.

- Growth Monitoring: Track the growth rates and feed conversion ratios of the broilers to ensure they are meeting the expected performance targets.

- Health Monitoring: Regularly check the health of the birds and promptly address any signs of illness or stress.

- Record-Keeping: Maintain detailed records of feed consumption, vaccination schedules, mortality rates, and production data to track the performance and profitability of the project.

Financial Planning and Profitability

Initial Investment

To provide a comprehensive understanding of the financial aspects, let’s break down the costs involved in setting up a 20,000 broiler cage breeding project:

- Broiler Cages: The cost of broiler cages in Zimbabwe can range from ZWL 15,000 to ZWL 50,000 per set, depending on the type and features.

- Feeding and Watering Systems: Automated feeding and watering systems can cost between ZWL 5,000 to ZWL 20,000.

- Climate Control Systems: Ventilation, heating, and cooling systems can cost between ZWL 10,000 to ZWL 50,000.

- Waste Management Systems: Manure removal systems can cost between ZWL 5,000 to ZWL 15,000.

Case Study: LIVI Poultry Equipment Factory

LIVI Poultry Equipment Factory, established in 1990, has over 30 years of experience in providing high-quality poultry equipment. As a powerful poultry equipment manufacturer in Zimbabwe, LIVI offers a range of products tailored to meet the needs of Zimbabwean poultry farmers.

Affordability and Quality

LIVI Poultry Equipment Factory is known for offering affordable chicken cage systems without compromising on quality. Their range of broiler cages in Zimbabwe includes both A-type and H-type broiler cages, designed to enhance productivity and efficiency.

- Competitive Pricing: LIVI’s products are competitively priced, making them accessible to farmers at various scales of operation.

- High Standards: All of LIVI’s products are manufactured to high standards, ensuring durability and long-term performance.

Comprehensive Product Range

LIVI’s product range includes a variety of poultry equipment designed to support the entire farming operation.

- A-type Broiler Cages: Ideal for small to medium-sized farms, these cages offer an affordable and efficient solution for broiler production.

- H-type Broiler Cages: Suitable for large-scale operations, these cages maximize space utilization and enhance productivity.

- Broiler Flat Farming Equipment: Supports a flat rearing system that promotes natural behavior in broilers.

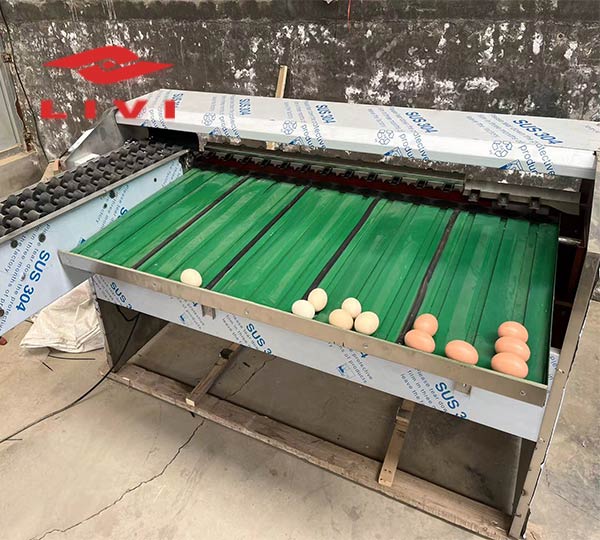

- Automated Auxiliary Equipment: Includes automated feeding, watering, and waste management systems that enhance efficiency and reduce labor costs.

Conclusion

Establishing a 20,000 broiler cage breeding project in Zimbabwe can be a highly profitable and sustainable venture. By selecting the right broiler breeds in Zimbabwe, investing in high-quality broiler cages in Zimbabwe.